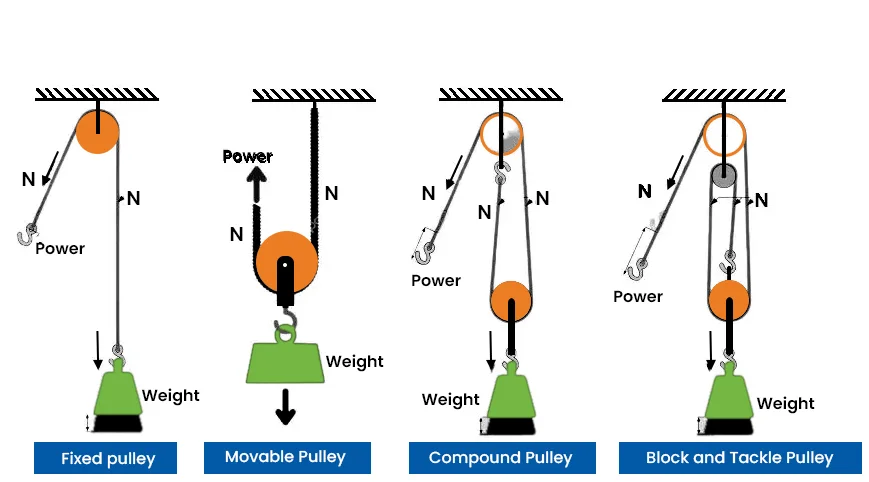

A fixed pulley has its wheel anchored in place. It changes the direction of the applied force but does not provide mechanical advantage. You pull down to lift a load up. Used in flagpoles, window blinds, and simple lifting applications where direction change is needed.

A movable pulley is attached to the load itself and moves with it. It provides a mechanical advantage of 2:1, effectively halving the force needed to lift the load. Used in construction hoists, cranes, and some gym machines.

A block and tackle combines fixed and movable pulleys to create a compound system that can greatly increase mechanical advantage. The more pulleys added, the less force needed. Used on sailing ships, theatre rigging, and heavy lifting in warehouses or docks.

A general term for any system combining fixed and movable pulleys to gain both directional change and mechanical advantage. Block and tackle is one type of compound pulley. Used in rescue operations, mechanical shops, and industrial settings.

This system uses one or more pulleys connected by a belt to transmit power and motion between shafts. Used in engines, conveyor belts, and manufacturing machinery where continuous rotation and torque transfer are needed. These systems can be configured to trade torque for speed or vice versa: for example, a small driver pulley and a large driven pulley produce more torque at the expense of speed, while a large driver and small driven pulley increase speed but reduce torque.